The past two weekends have been good with some great progress on the truck and trailer again! 😀

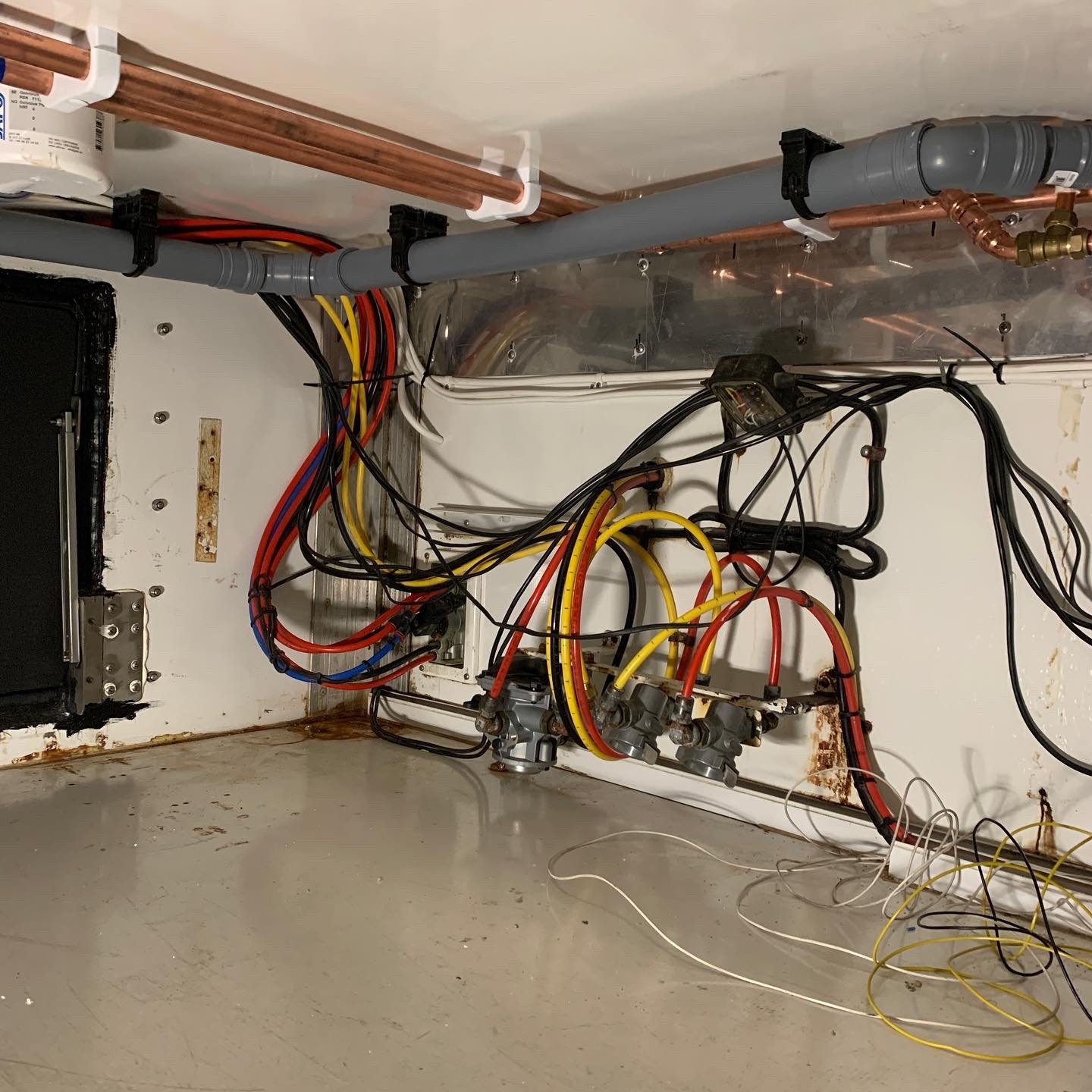

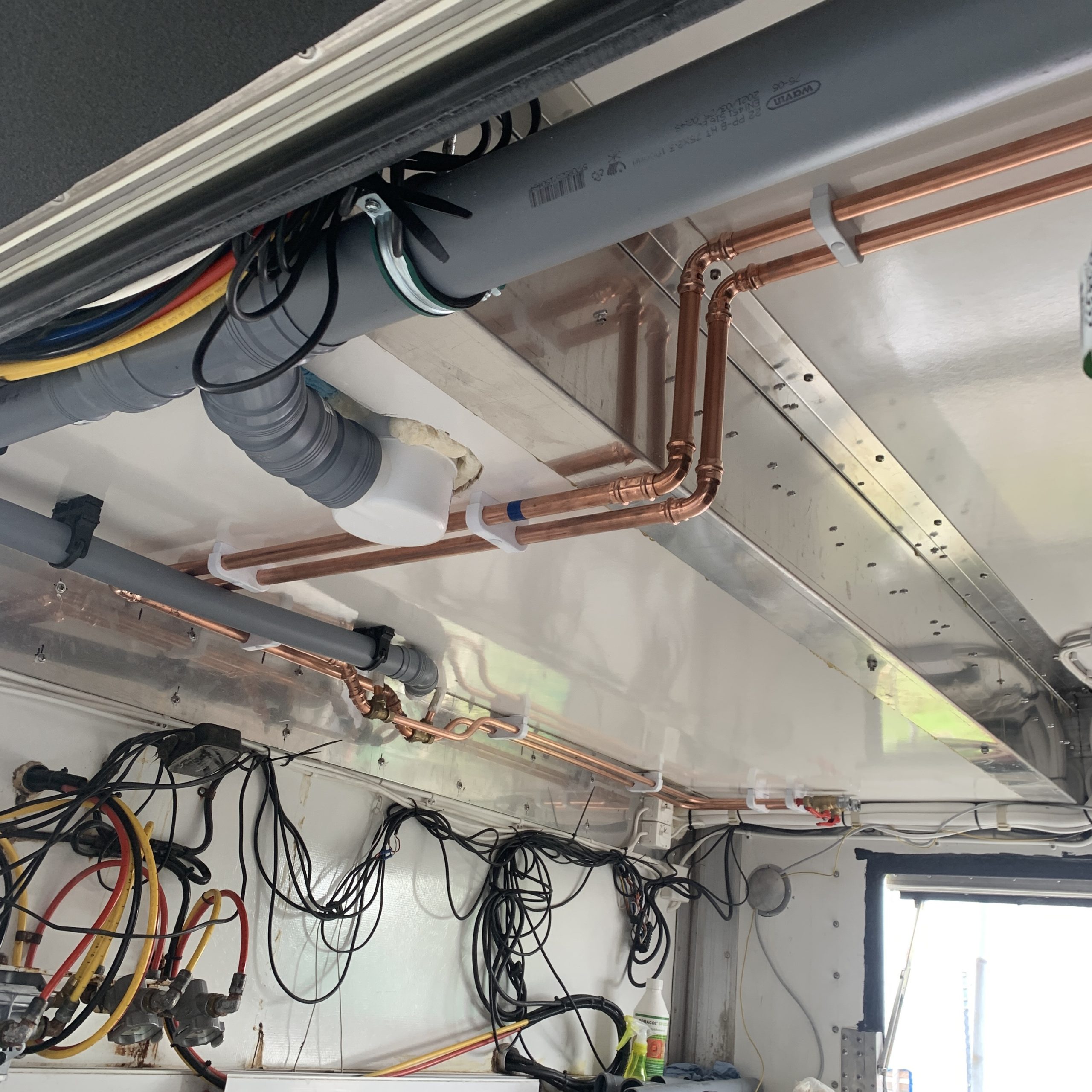

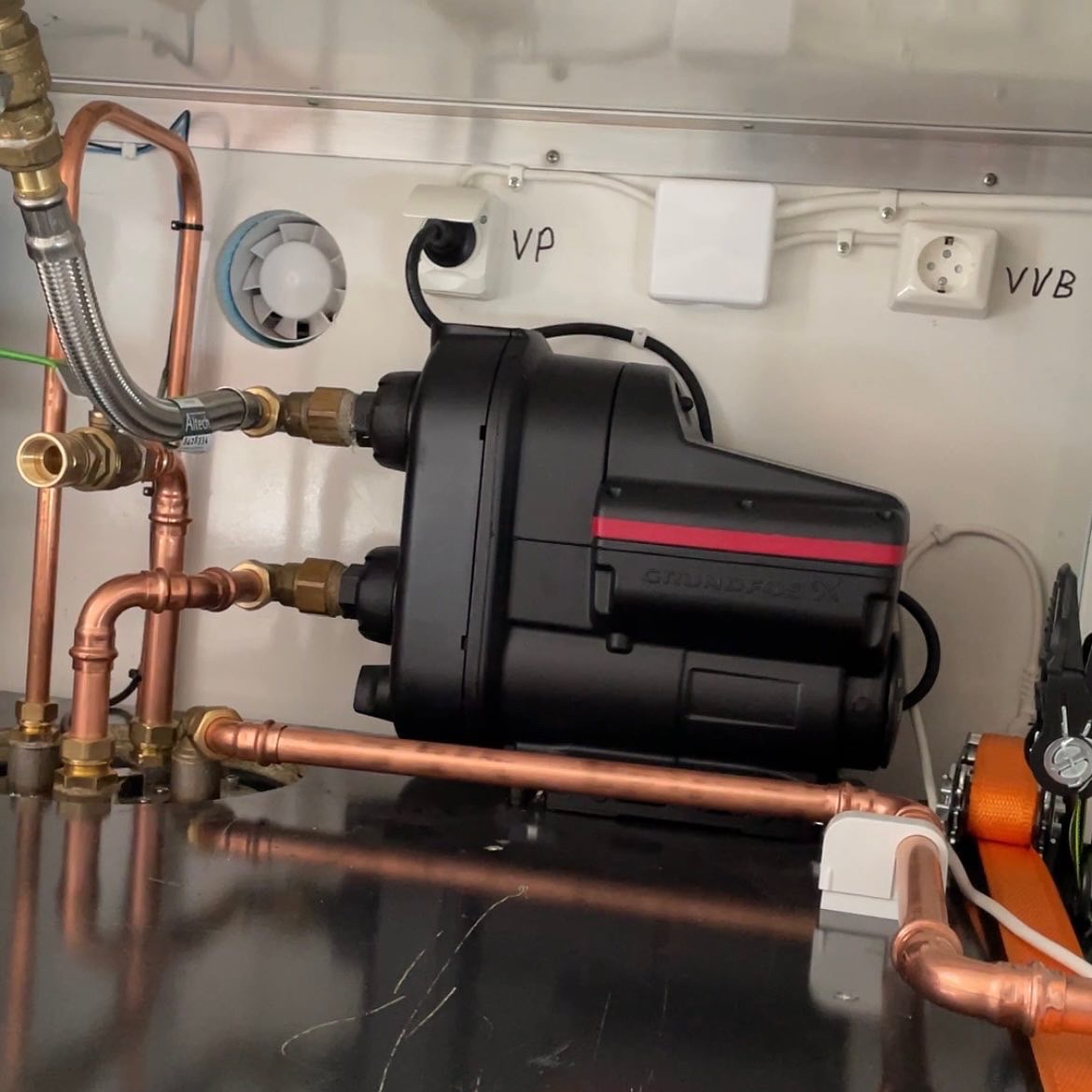

Me and Max did fill up some water in the fresh water tank for the first time and started the water pump and the water heater for the first time and everything did work just fine without leaks or so! 🙂 A huge thanks again to Peter and Patrik at Rörmekano in Vallentuna for their support helping us out install everything when it comes to the plumbing! 🙂

We did also finish up the front storage area where we have all the stuff outside in our pit space, we made some changes for a better storage and did put everything except for the tent in the trailer again, feels kind of crazy that we have packed almost everything 5 weeks before the first outing!

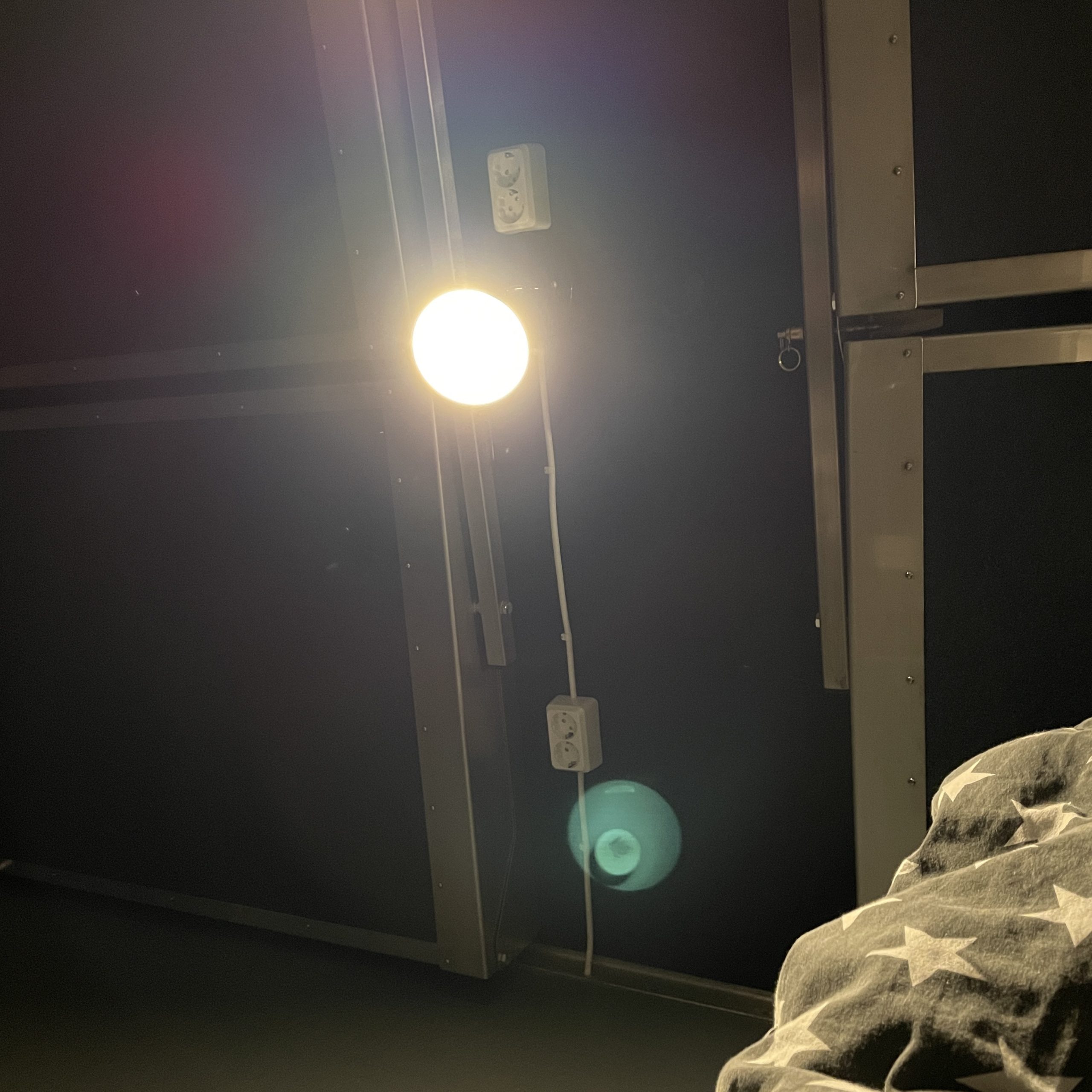

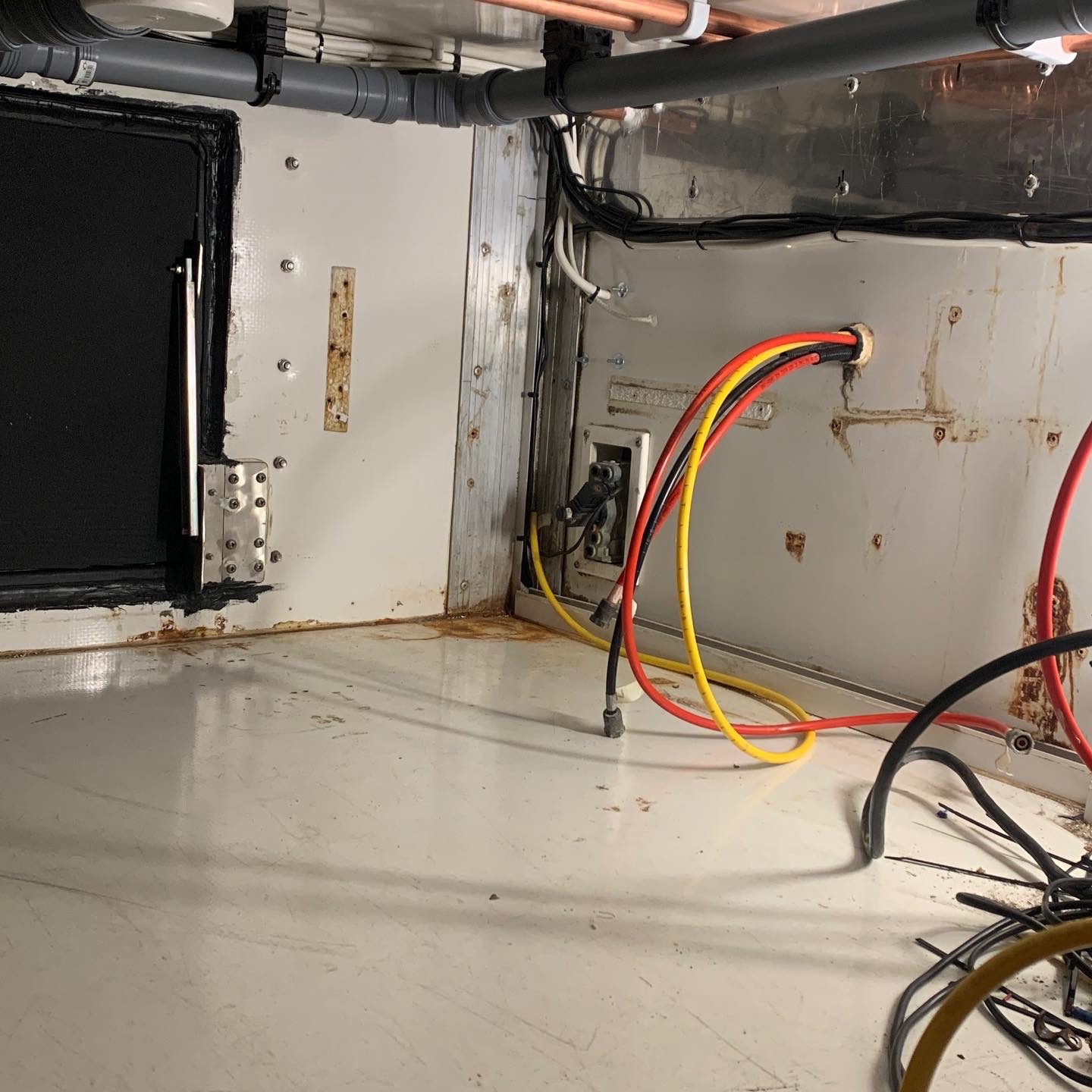

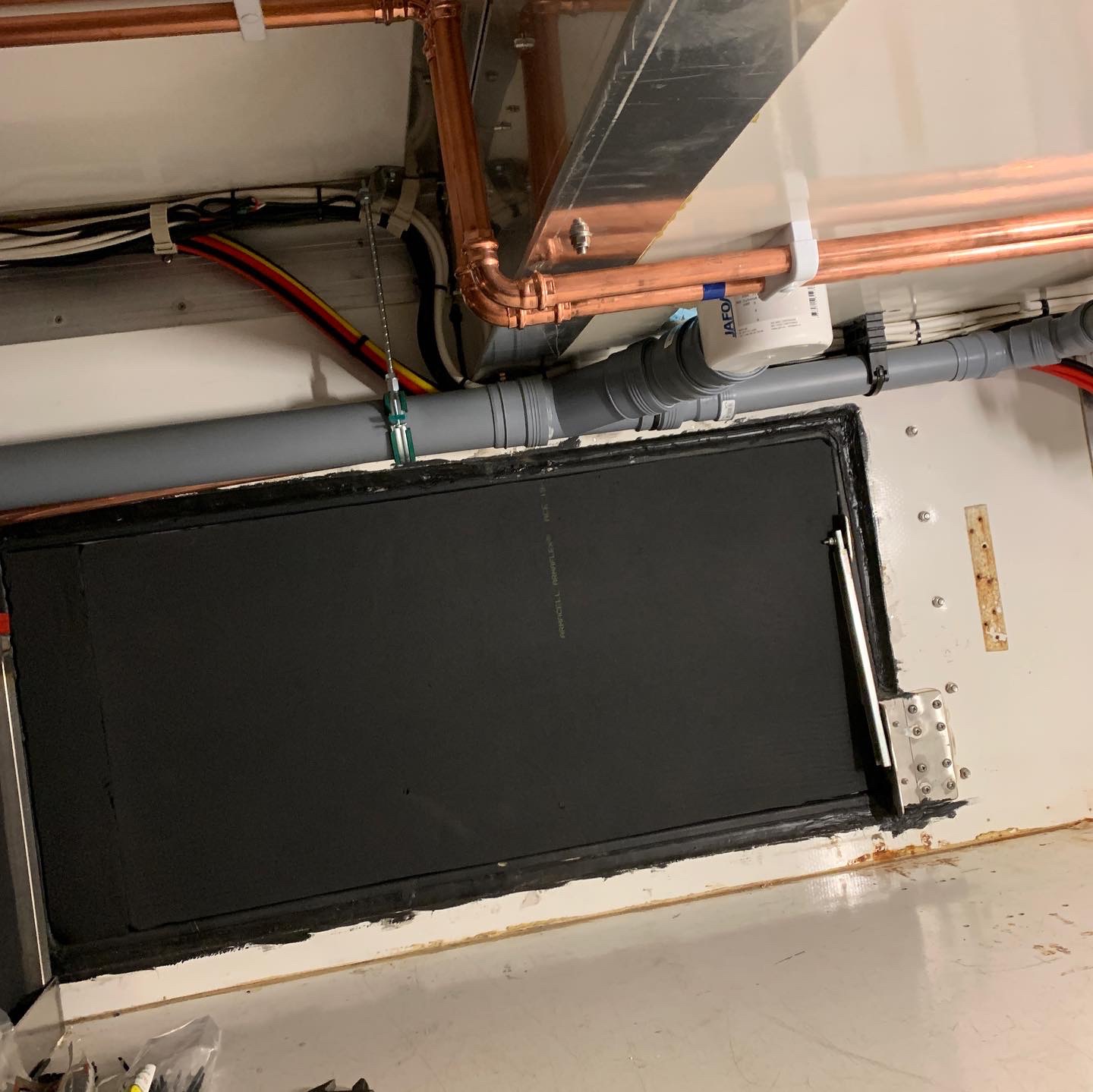

We did also remove the winter “insulation” on the lift gate that been sitting there for almost 2 years now because we are going racing again! 😀 We did install lamps in the rear part to help out when we load the race car in the dark, and at the same time we did finish up some small stuff to hide the plumbing to the lift gate, it’s all about the details! 😉

After that we got the fridges installed so they can’t move around after we changed them out almost a year ago!… 😉

Really not much left to do on the trailer now! 🙂

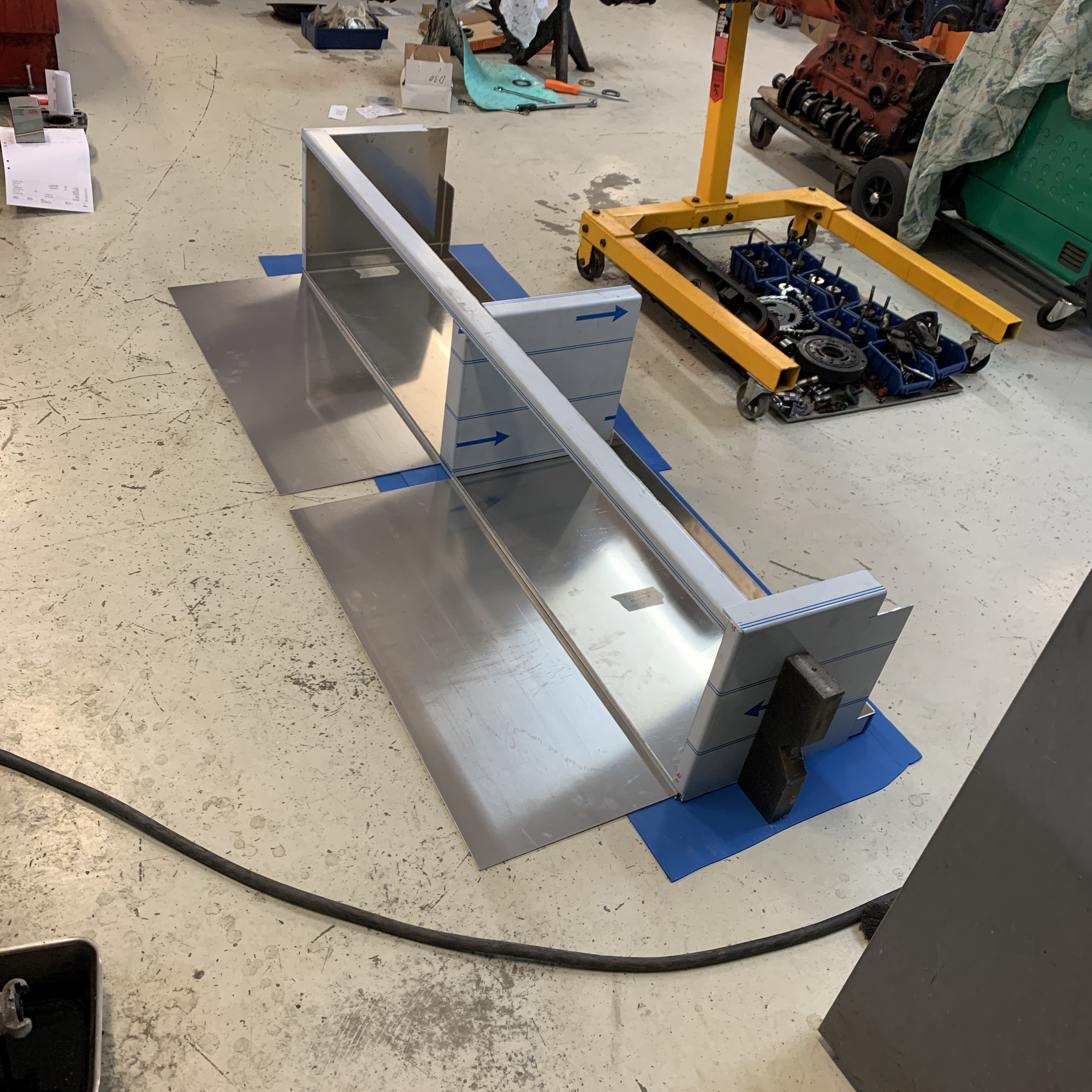

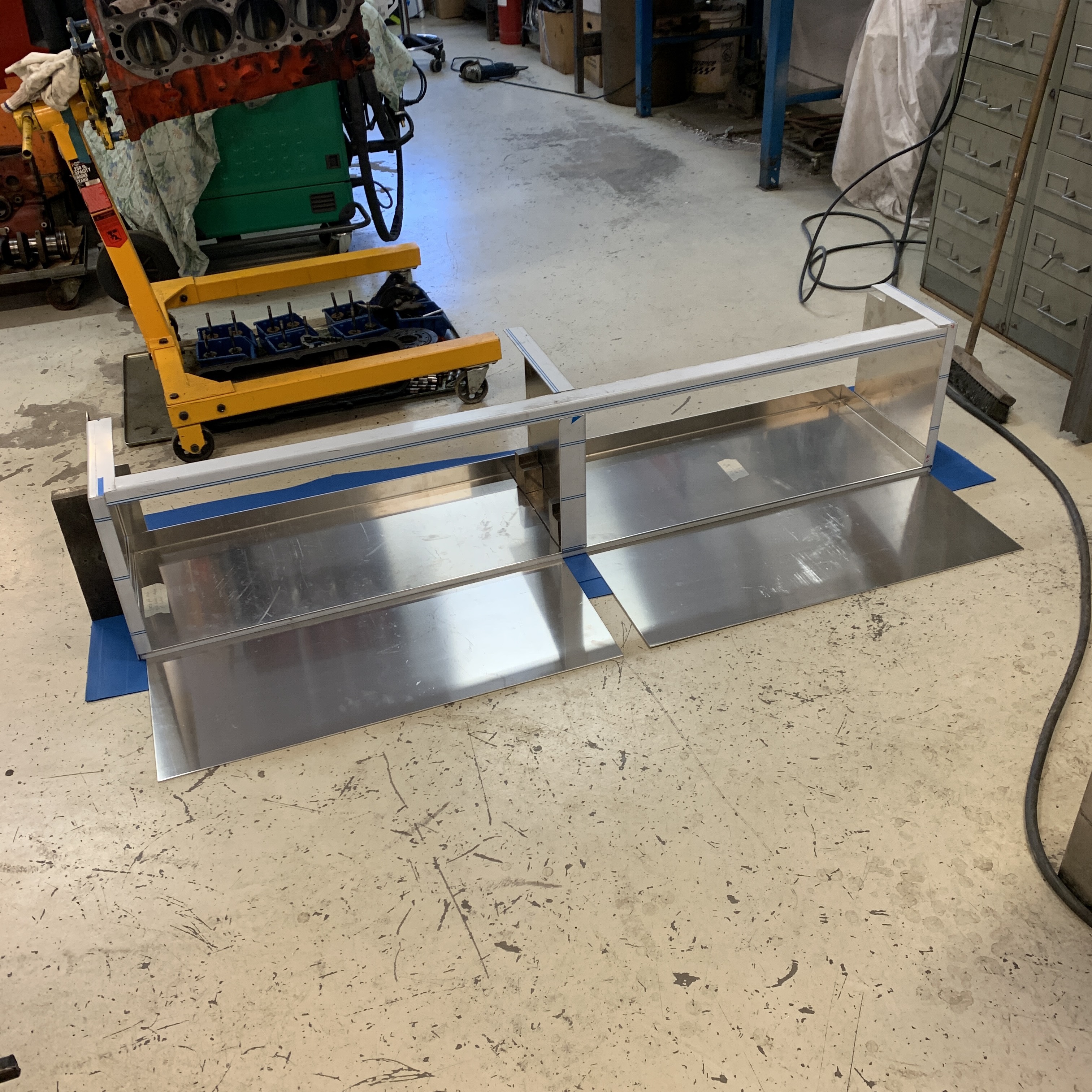

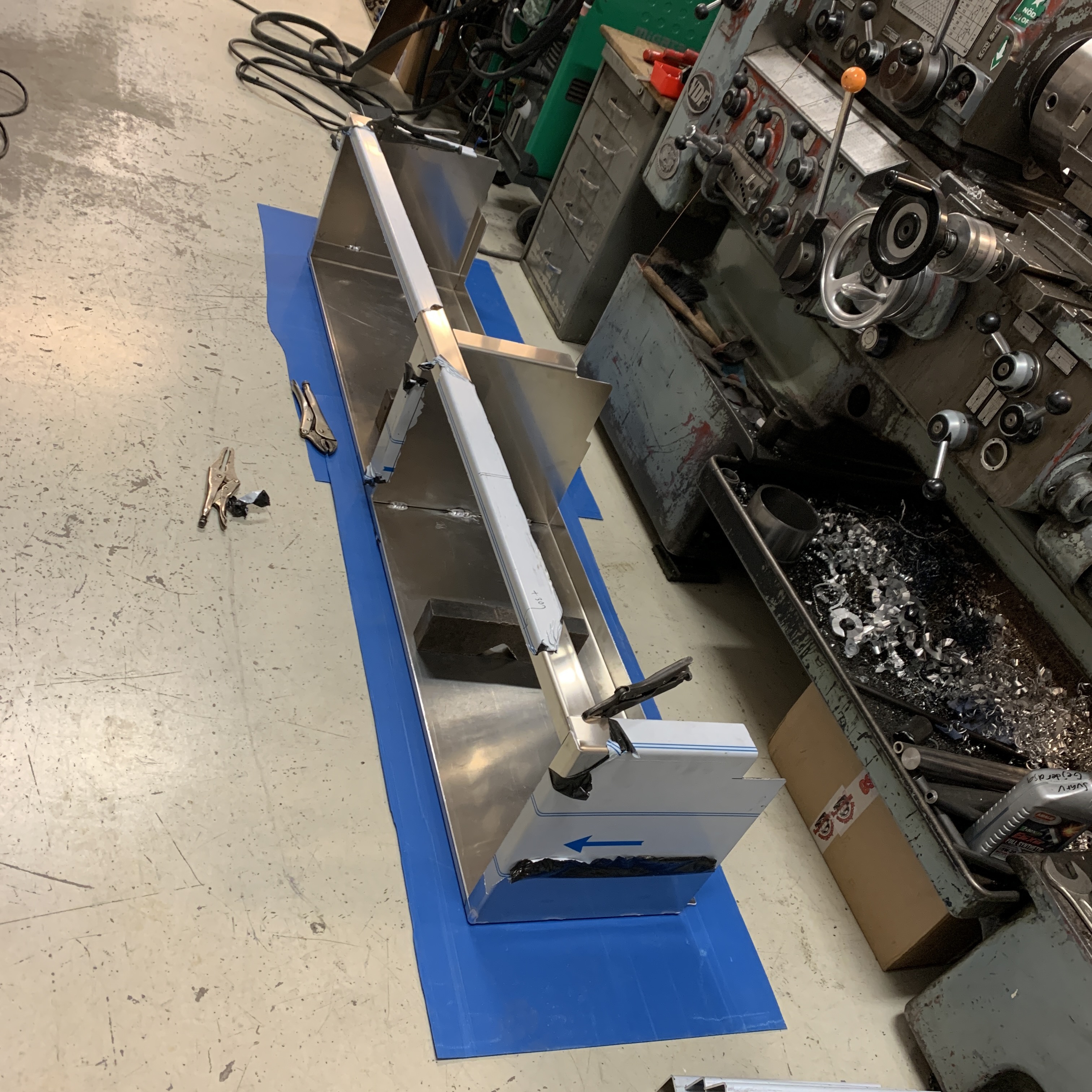

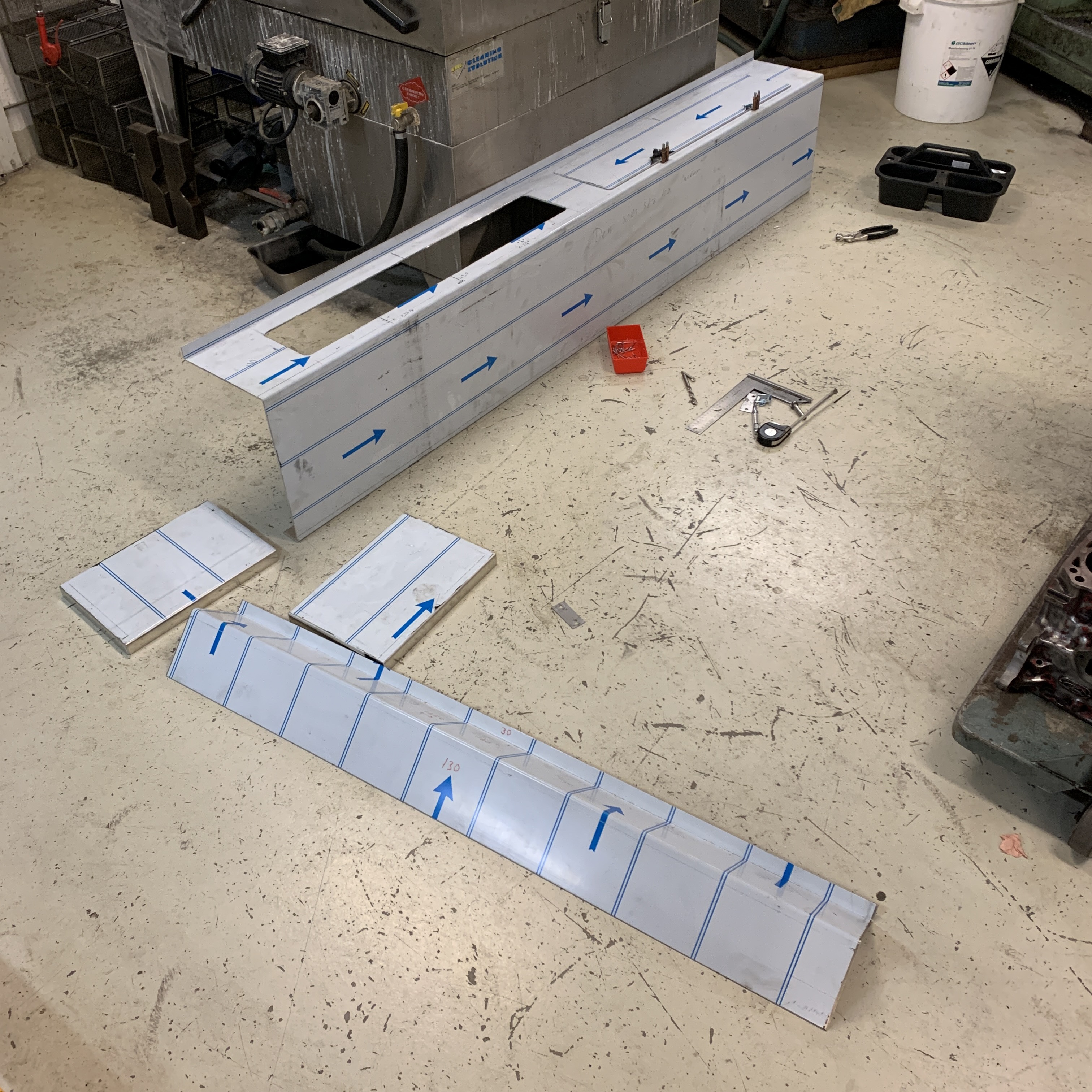

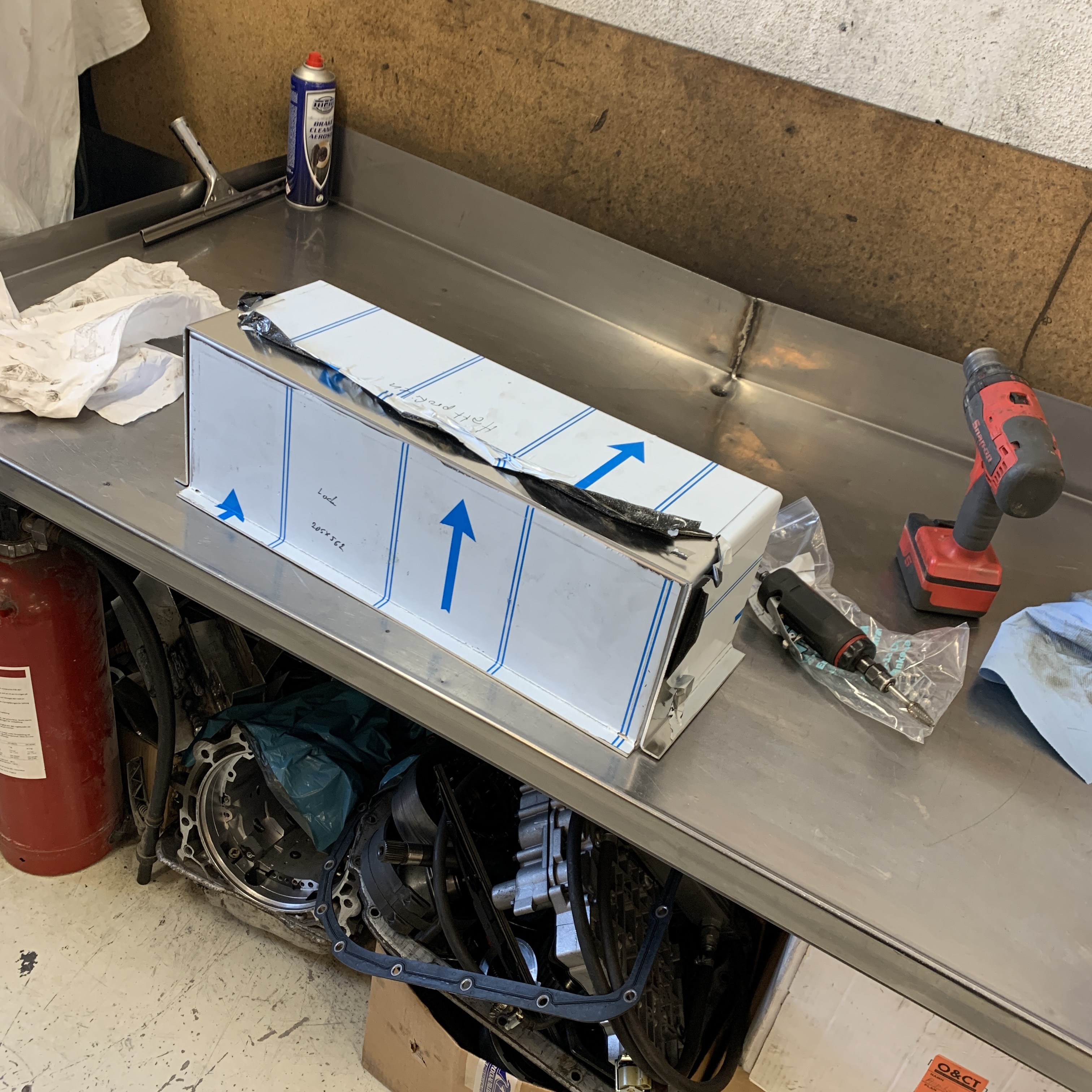

The week after I went by our partner Bengtssons Smide and got some material for a future storage box on the Scania Truck, thanks for your support! Really appreciate it! 🙂

And how freaking nice did this turn out!? 😀 We will really soon have a working sink in our tent / kitchen with fresh warm and cold water and also a pump station that gets the waste water to the waste water tank with some simple plug and play hoses! A huge thanks to our partner Peter at Rörmekano for swinging by today and finishing up the last piece of our plumping / water system on the trailer!

The week after we got a holiday that made us a longer weekend here in Sweden and that means trailer work! 😉 Plan all week was to work on the race car… but then work happened instead!… 🙁 So I did not have time to prepare stuff around the Chevelle for the planned weekend work! Anyway since Thursday last week we have been spending a lot of time on the trailer and on the Scania truck!

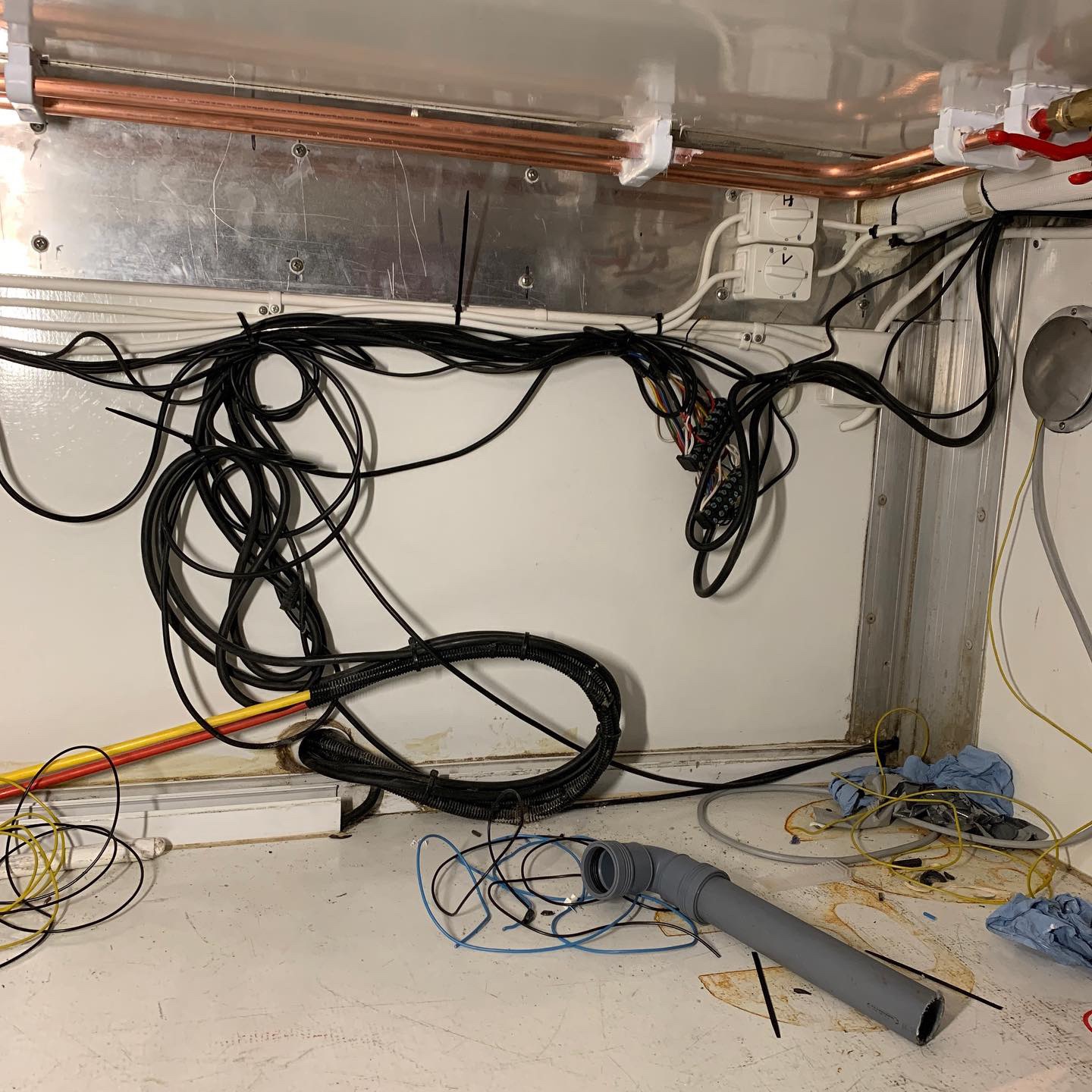

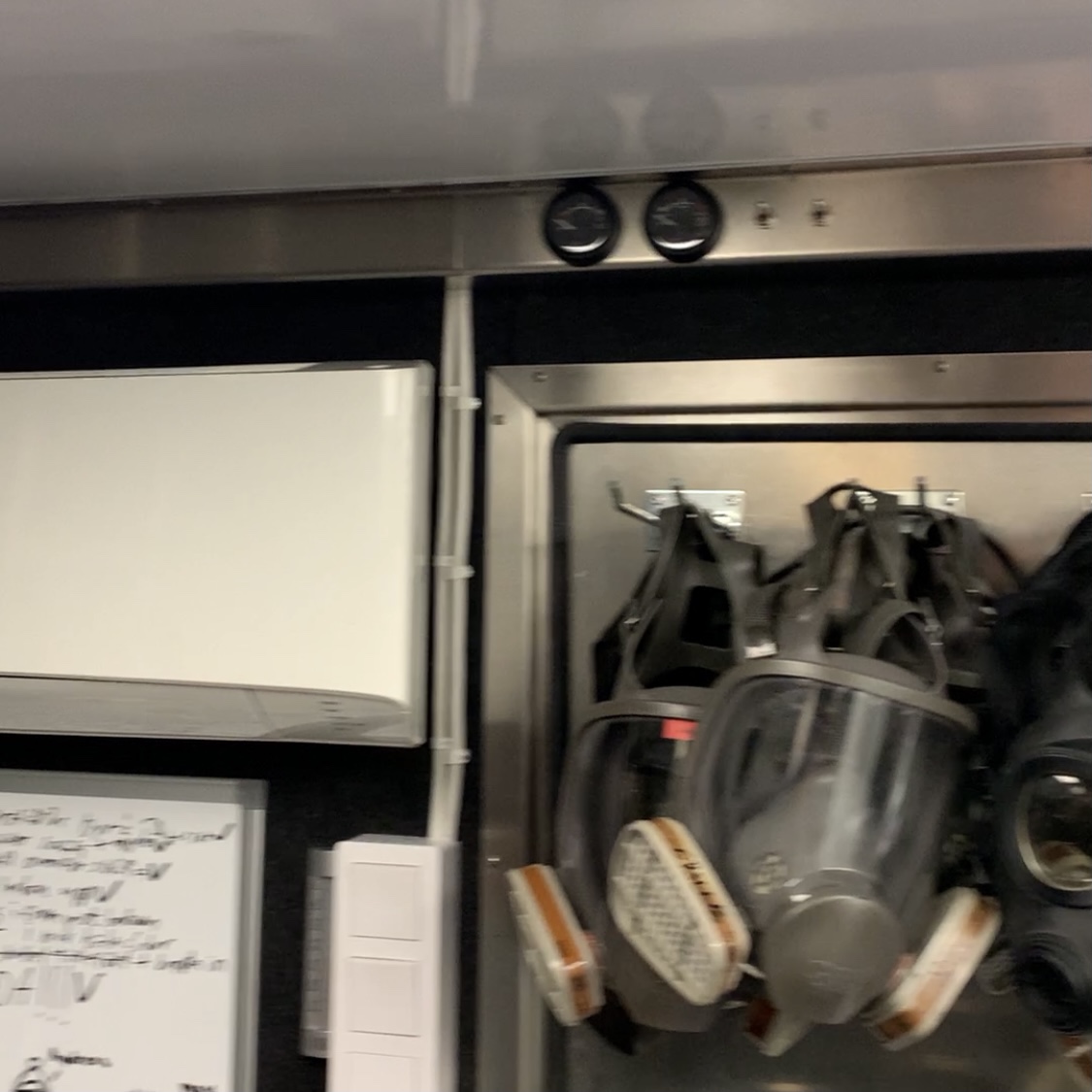

My old friend Dennis that was with me already already 15 years ago and also did help out a lot when I was modifying the body before making the mold and then the carbon fiber body have helped us out and finishing up all the electrical stuff in our roll out kitchens!

Krille from Sollefteå way up north Sweden is now a part of Sjödin Motorsport / ÅBM Racing and went down to help out during this weekend, good part with Krille is that he is a real fixer and can do what ever and that is something we really need in the team!

John the Snake have been here doing some stuff on the Scania and helped Max out with organizing the lights in our tents (in the rain of course) after 5-6 years finally!

Sofi have been cleaning up the roll out kitchens and organized them so we only got what we really need in them instead of way to much junk!

After a really long day it’s nice with some beers and just hang out! 😉

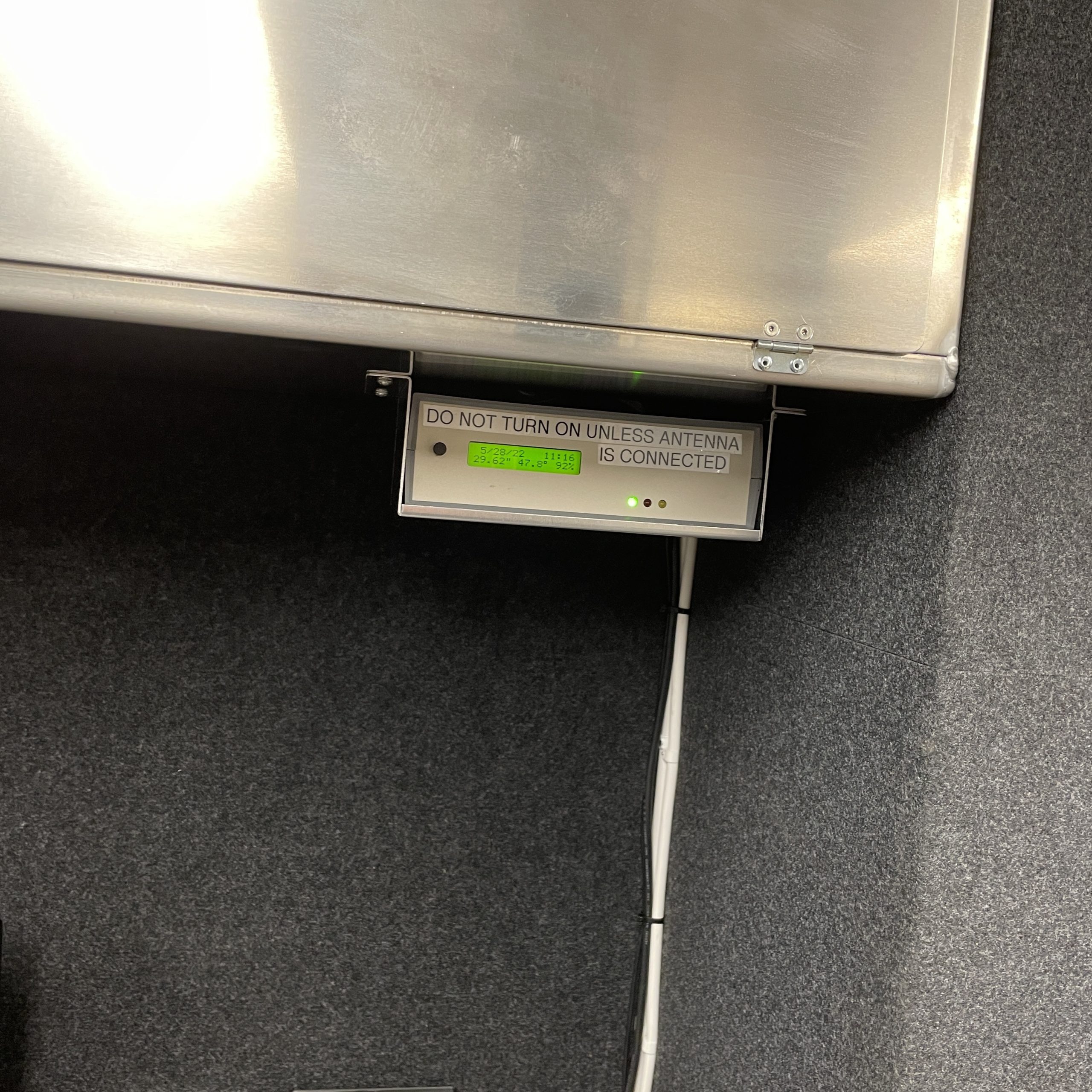

We also started to get the new trailer based weather station in place!

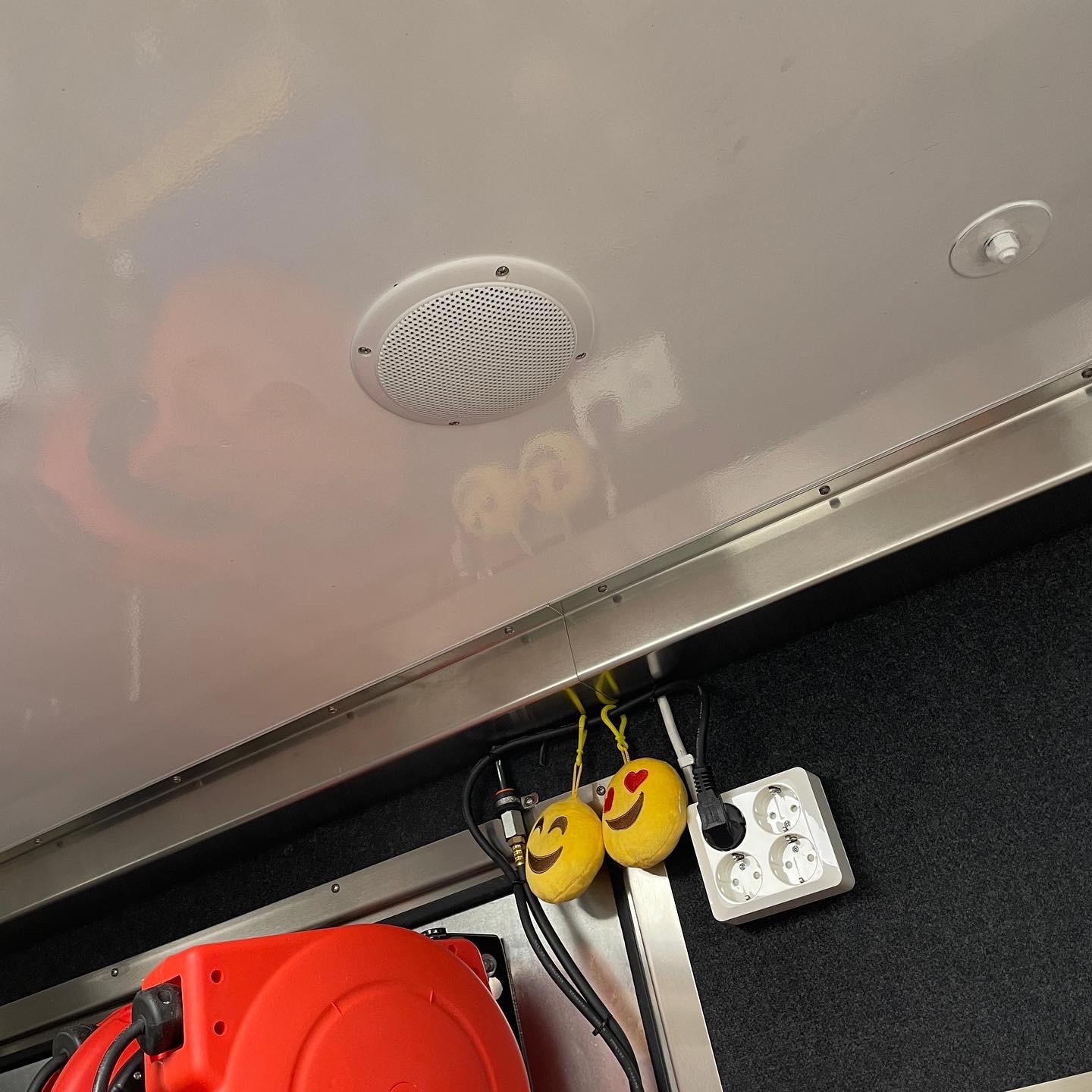

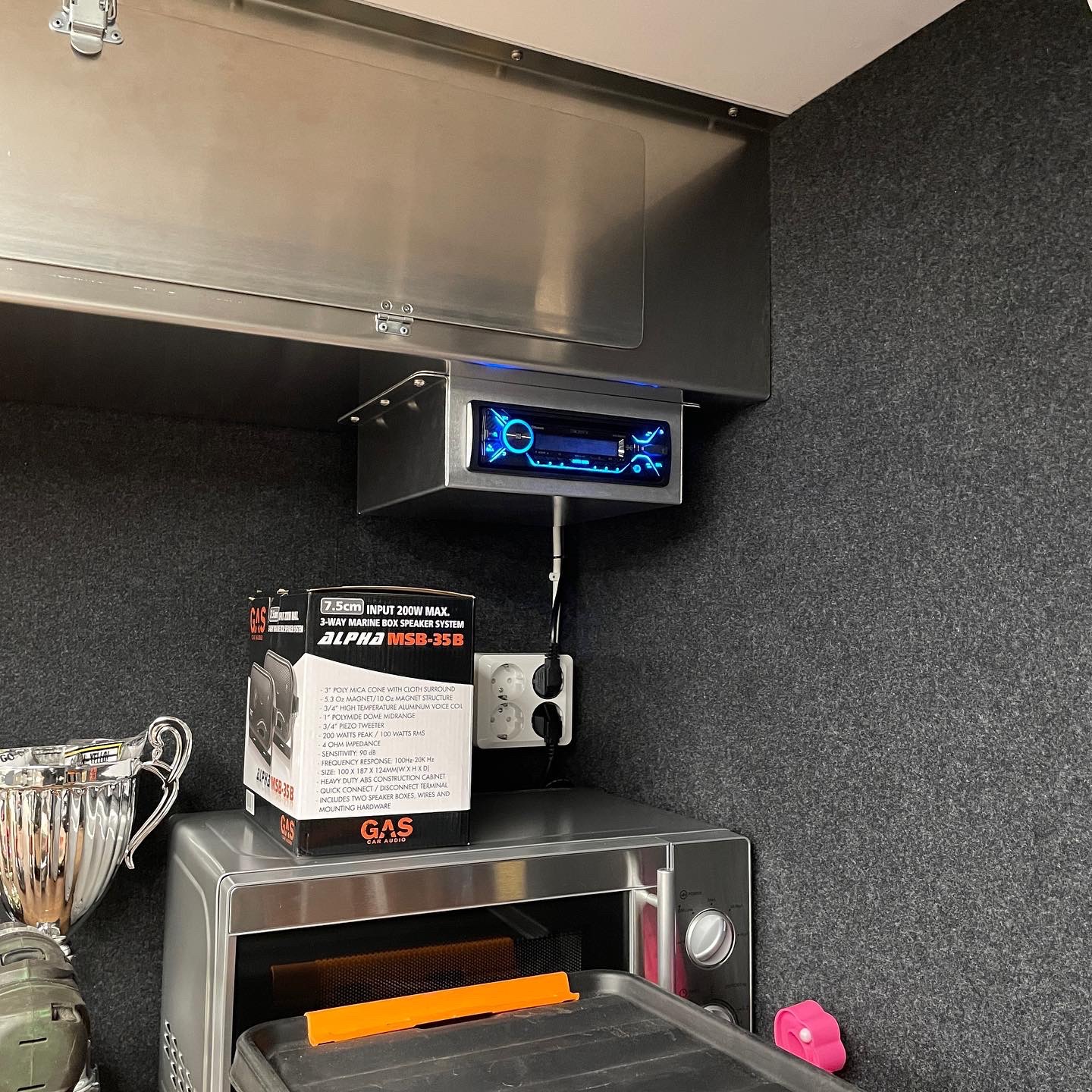

And we have finally got the stereo mounted after laying around for a year or so!

We have done some race BBQ practice at the shop on the new grill and Max is the man for the job of course! 😉

The front part of the trailer is finish packed with the tents so we are ready to leave the shop when it’s time for it!

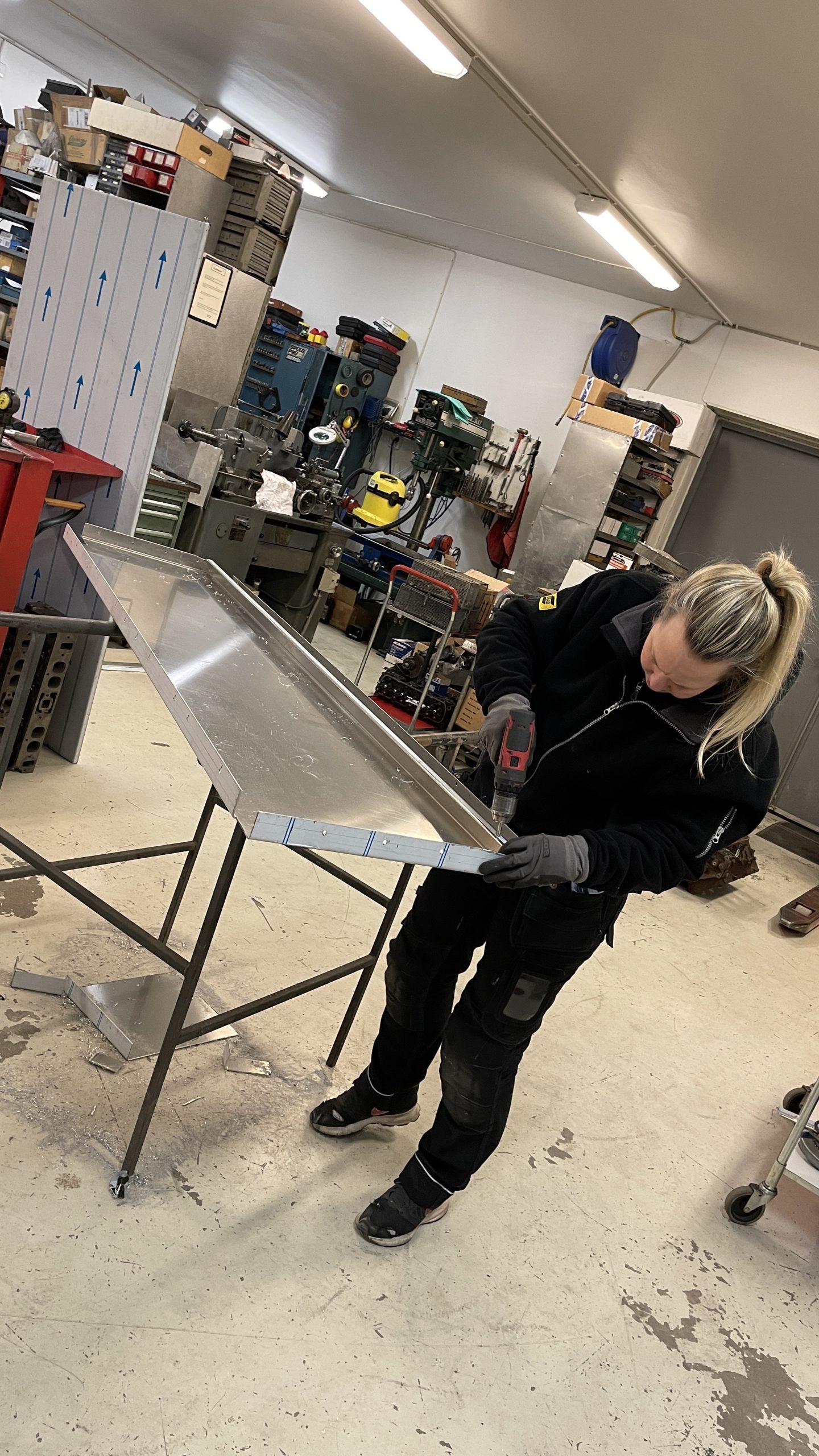

Sofi have done som welding fabrication just like always and also started on the new living room table, Krille have got the new generator in the right place!

We still have more from the trailer work weekend! 😉 During Saturday I was Superman for a while on a ladder on the side of the trailer wall drilling holes for the weather station sensor, yes it did of course rain because it was outside work!.. Like always!… 😉

So with that sensor in place we finally got the weather station up and running, feels good for sure because I have already sold the old one!

Sofi got our kitchens all done and even cleaned up!

After that Sofi and Krille got the new carbon fiber living room table in place, a table that got for over 10 years just laying around and finally found a place to use it!

Then during Sunday we got a tool for the Lenco made by Jonnie Lindberg Motorsports mounted on a bench in the trailer, a really good thing to help Max out when working on the transmissions!

After that we tested everything on our roll out kitchens, and thanks to Sofi everything is organized and clean, all electricity works thanks to Dennis and we got warm and cold fresh water and also a pump that takes the waste water to the tank thanks to Rörmekano in Vallentuna! A huge thanks for that! 😀

We finished up the weekend with some BBQ practice again, of course in a really nice weather, probably because we were done with all the outside work! 😉

Pretty much a real clean up of the trailer is all that’s missing right now! 🙂

Really soon it’s time to start work on the Chevelle again, kind of look forward to it! 🙂