Autumn 2005

A 1965 Chevelle was purchased. All removable parts was fiberglass with a tubular chassie with square-profile tube in the bottom. We got this because the price was right and I didn’t really know what to do with it at the time. All I knew was that it was going to be faster and better than my old ’64.

A 1965 Chevelle was purchased. All removable parts was fiberglass with a tubular chassie with square-profile tube in the bottom. We got this because the price was right and I didn’t really know what to do with it at the time. All I knew was that it was going to be faster and better than my old ’64.

September 2006

The original chassie was sold. The body was taken to Janne at Snowball Racing where a new chassie was built. The original plan was to race in the Super Smallblock class. Safety was a high priority so the chassie was designed according to spec 25:1E. Later it was decided that we would race in the Top Doorslammer class instead. Mainly because my father realised that racing in the Super Smallblock class would mean that we would have to put mufflers on the car. Of course this was unacceptable.

December 2006

The chassie is back in our own garage.

The chassie is back in our own garage.

May to September 2007

The build was put on hold because I was helping Max Hamrin with his Pro Street Morris Minor.

August 2007

It was decided that our Chevelle would have a full carbon fiber body. All the original fiberglass parts were sold.

September 2007 to April 2008

The original metal body was customized and rebuilt.

April 2008

.jpg) The body was taken to Swecomposite in Åkersberga to make a casting mold. I take a break during the summer to help the Lindberg Bros with their Nova.

The body was taken to Swecomposite in Åkersberga to make a casting mold. I take a break during the summer to help the Lindberg Bros with their Nova.

June 2008

The body is back from Swecomposite.

September 2008

Racing season is over so the build continues.

Oktober 2008

The chassie we build at Snowball Racing was sold because the placing of the engine was wrong. It would have caused us problems in the future because of the high power output from a big supercharged engine. Of course we could have fixed chassie, but it was decided that the simplest solution was to start over again from scratch. This also made it easier to build the chassie for the carbon fiber body.

This time i decided to buy my own tools and build everything from scratch in my own garage. This chassie was going to be 100% of my own design and my own ideas. I was tired of people telling me how to build my own race car.

December 2008

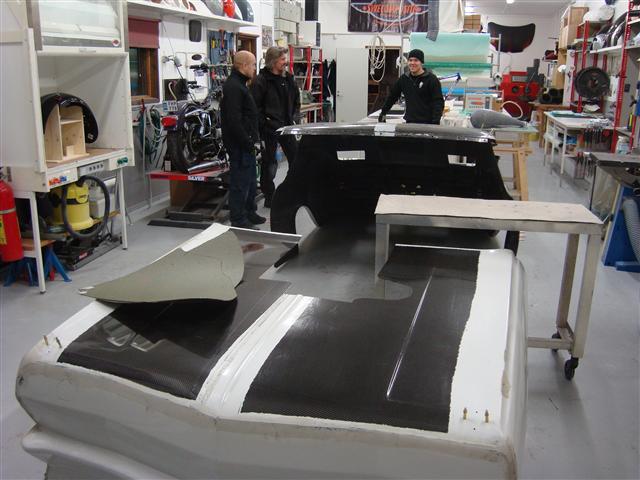

.jpg) The carbon fiber body is finished at Swecomposite and is delivered to the ÅBM garage. Now we also have our own chassie-jig and all the tools we need to build or race car 100% in-house.

The carbon fiber body is finished at Swecomposite and is delivered to the ÅBM garage. Now we also have our own chassie-jig and all the tools we need to build or race car 100% in-house.

January 2009

Building of the new chassie starts!

May to September 2009

Building stops. During the summer I help the Lindberg Bros with their Nova.

October 2009

All tubes is in the chassie. Everything around the driver is done and the carbon fiber body can almost be mounted to the chassie.

22 November 2009

The Chevelle is out of the jig and for the first time ever it stands on the ground!

The Chevelle is out of the jig and for the first time ever it stands on the ground!

14 January 2010

The first ever made-in-Sweden carbon fiber wheel tubs are finished!

6 February 2010

Once again things get out of control. The roots supercharger is sold and gets replaced by a PSI screw supercharger. HUGE thanks to Per Svedberg. This also means we will be competing in the class Top Doorslammer and not in Pro Mod.

15 March 2010

Carbon fiber body is taken to Johan Jarbeck at LSF Custom paint. Finally we will get some paint!

Carbon fiber body is taken to Johan Jarbeck at LSF Custom paint. Finally we will get some paint!

15 March to 10 Maj 2010

I take a break to find some inspiration

July 2010

Final assembly begins. The car is shown at “Day of thunder” in Nyköping, arranged by Nyköping Motorpark.

September 2010

The last parts for the engine shows up.

The last parts for the engine shows up.

Sept 16: First startup in the garage!

Sept 19: First test-drive!

The test drive was the end on this 4 year build. It’s been a bit of a bumpy ride, but right now it feels GREAT!

The Race Car

The car will compete around Sweden and in Norway in the class Top Doorslammer. It has a supercharged 526 cubic inch V8 running on methanol. Transmission is a 3-speed Lenco and we are using a clutch. This page will be updated continiously as the project evolves. (Ended in September 2010) Check out the photos below. Almost every picture is a link to a small gallery.

2010-09-19 First test drive!

Everything is finished except for small details and adjustments.

From now on please have a look in the pictures / movies section.

Build pics from 2010

Click on the pictures to get to the photo galleries

Week 37 |

We’ve been working more or less around the clock the week before the fist testdrive on Kjula Dragway Just like the two previous weeks we’ve been super-busy fixing the drive system and brackets for the oil pump etc, but finally we got it done! Fuel lines, oil lines, electric system, rear end, transmission, etc is in place. The chassis has been tagged and the engine has been fired up for the first time!!! 🙂 The car was loaded into the trailer on friday night, ready for adventures on Kjula Dragway. Huge thanks to Anders “Charley” Karling for all the help and for letting us use his shop! Also, big thanks to Erik Bengtsson, Tobbe, Alex, Crille Nilsson, Dad, Ulf Schill, Jocke Månsson, Johan and Jonnie Lindberg. We managed to get the car to the race track and give it 2 careful test-drives. This marked the end of a 4 year build. It almost makes me feel a bit sad. What am I supposed to do now? Jokes aside, this build has been pure hell from time to time, but all the and positive feedback I’ve gotten has been overwhelming. Thank you all! /Andreas |

Week 36 |

Finally the parts for the engine arrived! 5 days later than expected… But now the engine is back in the car! Been working around the clock for a week and finally the piece of garbage sold as an engine 2.5 years ago is assembled! It has been a lot of welding, drilling, cutting but now it’s finished! Good thing I know my way around the machine shop and have friends who are willing to help me out! Also the clutch, tranny and rear end is ready to be mounted! Tobbe and Crille has started with the wiring. To bad we’re behind schedule because of delayed deliveries of tools and parts. Huge thanks to Anders ”Charley” Karling for letting me have free access to his machine shop and for helping me with making spacers for the intake manifold! Thanks to Jocke Månsson for helping with the clutch and tranny! Thanks to Crille Nilsson who always helps me out in the garage! |

Week 35 |

Engine build!! 🙂 I’ve taken the dummy-engine out and as always, things doesnt work out the way I planned. I borrowed a tool for mounting bigger lifters in the engine block and of course it wont fit in my engine block. I was also expecting the pistons and crankshaft to arrive in Thursday but FedEx messed it all up and sent my stuff to Paris instead. Everything got delayed because I need the crank to continue working. Alex finished the drivers seat, Tobbe has been looking over the supercharger and Isak has mounted the fire extinguisher system. Big thanks to Rickard, the workshop in Åland for lending me the tool for the lifters and Isak for the help with the fire extinguishers! |

Week 34 |

Thanks, all tanks are done. Huge thanks to Erik Bengtsson at Bengtssons Smide for a great looking job! I have mounted the oil, fuel and catch tank. We also molded my ass into the drivers seat. The firewall is closed up, fire extinguisher nozzles are in place, and the engine is out of the car. If everything works out as it should we should have it running in a week or so! We also have a new member in the team, Alexander Forsberg! |

Week 33

|

Assembly continues! Coilovers and sensors have been mounted in the rear. Door opening, lock to drivers window, throttle wire mounts on the injector and welding bungs to all tanks are done. The rear part of the body is totally DONE! |

Week 32

|

Been outside and took a few pictures of the car. Hopefully a couple of them turned out good. Big thanks to Marcus for the help! |

Week 31

|

Back after a a well needed week of vacation! Time to clean up in the garage! I also took some time to just sit back and take pride of a damn cool the car looks!! |

Week 29 (Day of Thunder in Nyköping)

|

BIG THANKS!!! Big thanks to Tobbe, Dad, Isabell, John, Tomas and Kenneth from Swecomposite for all your help today! |

Week 29

|

This week has been insane. Got the body back from the paint shop and sice we wanted to have the car on display on the ”Days of thunder” event we’ve been working 24/7. We mounted brake lines, windows, the rest around the wheel tubs, stickers and a lot more. If you need brake lines, AN couplings, steel braided hoses, we now sell it! We bought a brake hose press to our shop! Contact us at www.akesbilmotor.com for more info! Huge thanks to Tobbe, Crille, Jocke from LL Racing, Tony, Snigel, Janne Jäger, Erik Bengtsson, PG from Bilglasdesign, Kenneth from Swecomposite and Mattias and Christer Westman. Without you, this wouldn’t be possible! |

Assembly after paint

|

Assembly after paint job. |

Paint by Johan Jarbeck from LSF Custom

|

Some photos from the paint job by Johan at LSF Custom Paint |

Week 28

|

Out in the open!! Mounted some more carbon fiber plates, mounted the rear axle, crank case ventilation, etc. We also received a mighty fine battery from our sponsor Gylling Teknik. PG from Bilglasdesign started with the windows for the car. Thanks!! Also a big thanks to Jocke from LL Racing and Tony who helped out in the garage. We took the chassis out for some photos, but if you really want to see the car, come to Days of Thunder in Nyköping on July 24! |

Week 27

|

Did some more work on the carbon fiber interiors and mounted the Racepak along with some other stuff. Erik from Bengtssons Smide was here to take some measurements for the tanks. Thanks again to Crille Nilsson for all your help! |

Week 26

|

Dad has almost finished the rear axle. The chassis is on the pro jacks. Feel a bit boring to be in the garage when the sun is really shining outside, but hey… That’s how it it. Big thanks to Crille Nilsson for all help! |

Week 24-25

|

Finished welding on the chassi! It’s insane to think about how much time you actually spend on welding! Mounted the firewall and the floor on the drivers side. I made some mockups of the rest of the floor. It’s going to be carbin fiber later. Erik Bengtsson helped out with some bending and some welding. |

Week 23 |

Here we go again! Been away from the garage to recharge, but now I’m back! I mounted the WOT sensor and clutch sensor. The chassis is finally out of the jig and I cant believe how much floor space the jig took! I also continued the welding on the chassis… |

Week 19

|

A Racecar Is Born! Started working again after a short brake. Worked for five days this week and I got some stuff finished. Drivers seat with mounts, safety belts, shift light, Racepak display and the tag for the chassis! Dad and Mattias has been working on the cylinder heads. |

Week 18

|

Some photos from May 5th when I was on the show Motorsoffan and discussed chassies. Click here to see the episode. |

Week 13

|

Not so much has happened this week. I’ve been working and reading Street and Strip. Really great job, Togga Liljedal! Super article! Tobbe has worked on the clutch and I got my connecting rods for the engine. I’ve been at the paint shop to look at the car and the results were amazing! It was so good that we actually started to come up with new ideas… |

Week 10

|

Been working like crazy again. I also did some work on another race car. We made some final adjustments prior to the paint job. I did some more work on the firewall. Tobbe worked on the wing and Johan finished the window templates. I ordered some race clothes. Thanks to JP Simpsons Sweden for the help! I made molds of my combustion chambers and ordered pistons. TTR Jompa helped me with some weldings on the heads. GREAT guy, GREAT job! Best of all, the body has been taken to the paint shop and Johan Jarbeck at LSF Custom! |

Week 9

|

Really focused putty-monkey on the photo BIG THANKS to John “Snake” for the body work! Must be something wrong with this guy. I cant believe he actually came back here after the last time I got the clutch certified, Aceton-Johan did some detail work on the rear lights, Kenneth from Swecomposite came over with a kick-ass carbon fiber seat for me to have in the race car! How cool is that?! |

Week 8

|

Did some body work in Swecomposites shop. Took the body back to my garage again. Thanks Johan Lindberg. Jonnie did some sheet metal work for the firewall, John “Snake” prepared the body for paint, Johan Svensson made some templates for the windows. Ulf Schill came over to help us make some coffee. He said he was really good at it… Yeah, right. 10 minutes later we had our entire office table covered in coffee… |

Week 7

|

This week I was to Swecomposite and helped them out with the body work. Erik Bengtsson did some more work on the fuel, oil and catch tank. I’ve also been welding for about 12 hours on the chassi. Not very exciting. We got 30cm of snow this week so it doesnt really feel like the summer is that close, but it’s coming! |

Week 6

|

Body has been taken to Swecomposite to get the mounts attached. Thanks Johan Lindberg! I was to the market in Åby and sold some stuff. I also met some really nice people! I got some rims with the right backspace for the rear tires and I got a new pair of cylinder heads. I also ordered a crankshaft and replaced the drivers seat. It just didn’t feel right to sit in… |

Week 5

|

More cool-stuff! I got out of control again. I traded the Roots-blower to a huge PSI twin-screw supercharger! OH YEEAH! BIG THANKS to Per Svedberg! Now I have to make a bigger hole in the hood again… |

Week 3

|

It’s been a messy week and I didnt get much done on the car. After a computer crash I’m back online and updating the website. I’m sure it’s just a matter of time before I fill this computer up with metal dust to… Jonnie has almost finished the upper part of the firewall. I worked on the rear wheel tubs and Erik Bengtsson did some measuring and sketches on the tanks and some other stuff he promised to help me with. BIG THANKS to my cusin Marcus who is my 24/7 support! |

Week 2

|

Wheel tubs are monted. Really cool to get something this big mounted to the car! Kenneth and Thomas from Swecomposite did a really good looking job! Jonnie did some more work on the firewall. He really knows this stuff! What a guy! Thanks Jonnie Johan made some adjustments to the office door, so now it actually opens all the way. Johan also made a quick time-lapse movie from when we mounted to wheel tubs. Click on the link below to see it: http://www.youtube.com/watch?v=PFi8JPIN72c |

Week 2 at Swecomposite

|

Carbon fiber wheel tubs are made by Swecomposite in Åkersberga. Some pictures from the manufacturing process and a small film clip below. http://www.youtube.com/watch?v=IquBaPHs-ps Contact www.swecomposite.com for price and more info! Andreas ÅBM Racing, design Erik from Bengtssons Smide, manufacturing of template. Johan from LSF custom, painting of template Kenneth & Thomas på Swecomposite, manufacturing of the first Swedish made carbon fiber wheel tubs! Very cool! |

Week 1

|

Didnt get so much done this week. I took the wheel tub template to Swecomposite. Big thanks to Johan from LSF Custom paint for the paint job! Did some thinking about the firewall. We’ll have this done by next week. Hopefully |

Build picsfrom 2009

Click on the pictures to get to the photo galleries

Week 53

|

Rest makes everything more fun! Finally I got some motivation back! I monted the sliders for the Lenco transmission, blowback brace for the clutch shield, pressureized air tube, fresh air tube, redardbox, Racepak, mechanism for the clutch, throttle wire, wire for fuel-cut, crank case breathers to the frame etc. I got some help from the smaller Lindberg-bro who monted the window nets. We also started thinking about how to build the upper half of the firewall. We want it to be easily removable. |

Week 50-52

|

These weeks has been kind of dead in the garage… Template for the wheel tubs has been taken from the manufacturer (Erik Bengtsson, Bengtssons Smide) to the painter (Johan from LSF Custom paint) |

Week 49

|

Again, big thanks to Erik Bengtsson! Erik helped me to build the template for the wheel tubs! This will be used later by Swecomposite to make the carbon fiber wheel tubs. I also think I have sorted out where to but the retard box, Racepak and the bottles of air. |

Week 48

|

How unexpected! I was supposed to take it easy but I couldnt help myself. I welded the projack mounts to the chassie and did a test-lift. COOL! I also got myself Christmas gifts from the states, so now I know where I’ll be spending Christmas Also did a lot of work on the homepage. |

Week 48

|

Photos! We rolled the car out into the daylight and took some photos. Thanks Johan! |

Week 48

|

Photos by Marcus Sjödin I never thought the rain would end, but in the middle of the night it did! We rolled the car out for some photos. Thanks for the help Marcus! |

Week 48

|

Old American carl! 🙂 450 hours in 12 weeks since I started again after the summer break the Chevelle is standing on the ground for the first time! Feels really good to have come this far! Thanks to everyone who helped me get this far! |

|

Finally empty! Thanks Dad, Snail-man, The Pirate, Musta, Johan, Tina, Mange and Snake for the help to get the chassie out of the jig. |

|

It’s close! 2009-11-22. A very satisfied chassie-builder, a few minutes before the creation will be removed from the jig and placed on the ground for the first time! |

Week 47

|

Zoomie-headers are done. It took quite some time to build but they turned out really good! Parachutes are mounted and we prepared to get the chassie out of the jig. Thanks to Erik Bengtsson who helped to cut some mounts for me! |

Week 46

|

Rear of the body monted. Doors and front are in place. Almost done with the mounting of the parachutes. I’ve started working on the zoomies.. |

Week 45

|

Real lights are a must-have on a real ragger-car. Almonst the entire body is mounted. It turned out really good! I also mounted the first dzuses in the car. We started building the mounts for the parachutes in the body and chassie. I did some more welding and we cut some more carbon fiber. And yes, this time was also a mess! Good thing the time is 00:45 right now and a new week has started. Huge thanks to Krille who has helped me this entire weekend! |

Week 44

|

Back from the states! More inspiration to work! The front suspension is done and the mounts in the doors have been molded in place by Swecomposite. The body has been fine-tuned on the jig and assembly has started. |

Week 42

|

Frames for the doors are done. Front engine plate with mounts are in place. I rebuild the forward/reverse shifter for the Lenco. We prepared for the mounting of the body. The last bits of the office is done. Big thanks to John for the help with the electricity. On Wednesday I’m going to the states to watch the ADRL finals and get some inspiration. |

Week 41

|

Only the Sunday was spent on the car, so we only got some work on the frames for the doors done. We also spent 3 days cleaning in the garage. It was needed! It’s so much more fun to work in a clean garage. Thanks to Janne Jäger for the help! We also built a small coffee-room and the Snail-man showed some great snailing-skills! |

Week 40

|

I got the body-mounts in the chassie in place, both in the front and the rear. I also mounted the kill-switch, trigger for the fire extinguishers, and front motor plate. I also got some help from the Pink Panther. I’m not sure how he helped, but I’m sure he did something. |

Week 40 at PW

|

PW Svets och Smide i Krylbo. Me and Jonnie visited Patrik Widd and made sure he got a long day of work with the water-cutter. We cut some pieces Jonnie designed for me. I need one of those water-cutter! Big thanks to Jonnie and Patrik! |

Week 40

|

Body test-mounted! Yaay! Only some fine-tuning left for the body to fit 100% perfect. I cut out some unnecessary carbon fiber that was left from the manufacturing process. Holy crap that stuff itches for days! I started building mounts for the front engine plate, decided where the fire extinguishers will go, and some other small stuff. Jonnie was here and made some sketches for some body-mounts that will be cut in a water-cutter. Hopefully I can mount the body during week 40. |

Week 39

|

|

Week 38

|

Mounted trigger for parachutes, finished the gas-pedal, mounted the front driveshaft ring and tunnel and mounted the shifter buttons. Only thing left is the trigger for the fire extinguishers. I finished the projack in the front, started on the exit of the crank case ventilation in the frame and we put a part of the old metal body on the wall as a piece of memorabilia. Tobbe and Danne ”The Pirate” helped me out some this week. “Tok Åke Bagarn” came here to visit. Very flattering to have a childhood idol tell me how impressed he was with my project! It makes it even more fun to work around the clock in the garage! |

|

25 hours spent in the garage this weekend and we got some results! Thanks Jonnie Lindberg for the help! |

Week 37 weekend

|

We mounted the last tubes in the chassie, brake lever, brake cylinder, steering column, and test-mounted the zoomies. Looks great! It’s so much fun to scratch things of the to-do-list! I tried Johan Lindbergs racing-outfit on. Feels great. |

Week 37

|

Added some more tubes and made some sketches on steering-column designs. The monkey in the cage is my cousin Tobbe who will help me out on Mondays. Thanks monkey-man, I appreciate it. Dad helps me out on Thursdays. |

Week 36

|

The rear projack mounts on the rear axle are done. We put the wheelie bars up on the wall since they’re finally done. (Fully welded) Next step is to finish the cockpit, and considering how well everything flows right now, it shouldn’t take long. |

Week 35

|

RESTART!! Summer’s over. Time to get something done in the garaget! Started cutting the hood and test-mounted the front of the body. COOL! This gives me work-lust! I’m trying to remember where I left off… |

Week 23

|

Drivers seat and belts are in pace! Jonatan came to visit. I think he thought it smelled bad in the garage. |

Week 15-16

|

Oil and fuel tanks are starting to take shape! Big thanks to Erik Bengtsson!I’ve been looking on how to mount the drivers seat, and I think I have it all figured out. |

Week 14

|

Yes! Wheelie bars are done!!! As usual, everything takes more time than you first think. I spent 17 meters of tubes constructing the wheelie bars Thanks to Tobbe who helped me out 2 evenings this week. The happy mechanic Dennis came back from a 4 month trip to Thailand. Lovely, I need more help in the garage! |

Week 13

|

Rear frame is DONE! I’m just missing 8 more tubes in the chassie, then it’s time to complete all the tack-welds. But before that we need to mount drivers seat, steering column, pedals, break-lever, brake-cylinder and wheelie bars. Erik Bengtsson from Bengtssons Smide in Täby got started on the fuel and oil tanks. Big thanks!! |

Week 12

|

Stefan ”Snackis, Tullingeälgen, Ollonet” Glantz came by the garage with a small gift. It was a sign with me walking with Snail-man in a leash. Big thanks! More beautiful stuff decorate the garage wall. Dad came by the garage and the first thing he did was to clean up. I said he would probably get crommolly cancer if he didn’t. I cant understand what he meant by that… Rear engine plate is done and in pace. Ignition box and coil is in place. Crank case ventilation in the chassie is done and I got some more tubes in place. |

Week 11

|

More tubes welded in place. Surprised? Everything around the tanks is done. Oil filter is mounted. The wishbone kit turned out to be total garbage. The only useful thing was the uniballs. Good thing I know my way around the machines in the garage. Rear frame started! |

Week 10

|

The brothers came to help me out. Jonnie worked and messed around a bit. Johan test-drove the chassie and though it worked better than the Nova Steering rack, firewall reinforcements, mounts for the rear engine plate and most of the stuff around the fueltank is mounted. Some 4-link stuff got done, and the front with wheels were test mounted. Cool! |

Week 8

|

Engine is test-mounted. Now I need to get the front suspension in place. Stuff is getting done! |

Week 5-6

|

4-link plates and the funny car cage is in place! |

Week 4

|

Not so much happened this week. Some work on the doors got done, body has been removed and I now have a clock in the garage. |

Week 3

|

Some progress was made in the garage this week. The Lindberg brothers are on a diet to lose weight before the summer |

Week 2

|

Body is mounted on the jig in race-height. Doors and A-pillars have been cut and everything fits perfectly. We got the main arch in place and some more tubing in the floor. |

Week 1

|

Last things on the chassie jig are done. The middle tubes in the chassie are in place. We made wooden wheels and we took measurements to match the body to the jig. We cut some carbon fiber, and I can assure you it itches like CRAZY |

Build pics from 2008

Click on the pictures to get to the photo galleries

|

Snailman is super-excited the new tube bender got here from the states! It took 11 days and 7 of them we’re holidays. I wonder why it had to take the Italians 3 weeks to get their crap here… So now Sjödin Motorsport in Täby can bend 4130 Crommolly tubes in the sizes 3/4″ 7/8″ 1″ 1-1/8″ 1-1/4″ 1-1/2″ och 1-5/8″ with thickness 0.058″- 0.134″ Good to know if anyone need help with their race cars! |

2008-12-30 Body on the jig

|

Home from Spain. We lifted the body on the jig. Of corse we needed a test-drive Johan Lindberg wondered if there was any tire-smoke, and YES! We couldn’t be in the garage for hours! |

2008-12-18

|

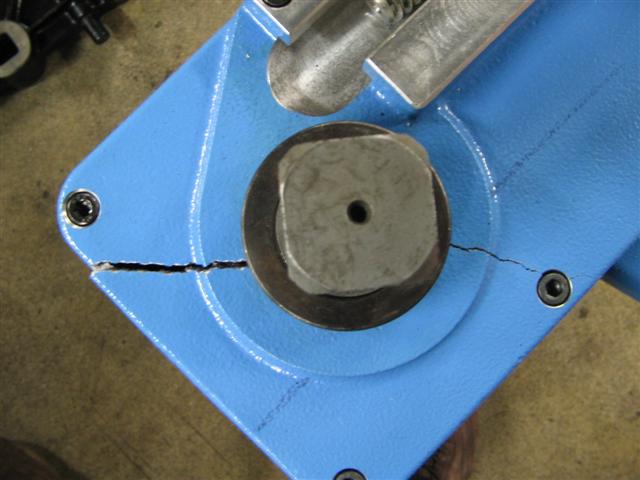

Damn it sucks to buy stuff sometimes. The seller told me that shipping would be 2 weeks, but with wrong deliveries and some hassle it was 6 weeks before I got what I paid for. I’ll never do business with Italy again. And when I tried to bend a tube, the bender cracked. I’m really disappointed but I’ll get my money back. When I do, I’ll buy a bender from the states that I know will do the job properly. I also bought a tube notcher. It worked really good after i made some own rolls in my lathe to get the right diameters. |

2008-12-16

|

Chassie jig got new mounts for the strut towers and rear axle. Now I need to adjust the height of the chassie and body. (Race height) |

|

Body back in the garage. Feels really good to get all the pieces into the garage! I can almost see the light in the end of the tunnel. |

|

It’s so light! I look lika a happy racer, dont I? Here’s some pictures taken by Kenneth during the manufacturing process. Pics taken by Kenneth at Swecomposite |

2008-12-12

|

Look! A carbon-fiber master! (Kenneth) Yaay! The last pieces have been picked up from Swecomposite. The last things to do before paint is small adjustments here and there, and to mold the chassie mounts to the body. |

2008-10-20

|

Almost done with the jig. I’ll just have to wait for the rest of the body from Swecomposite. It’s going to be a long winter! |

2008-10-17

|

It’s good to have some crommolly tubing in the garage! I picked up 180 meters to the chassie and about 6 meters beams for the jig. |

2008-10-17

|

Cool stuff! Picked up the front and doors from Swecomposite. |

2008-10-12

|

Chassie sold! The madness continues… During the building process I’ve learned a LOT. I discovered that the placing of the engine was totally wrong considering how much power we’ll have in the engine. To rebuild the chassie would be to much work so I decided to start over. The old chassie was sold to Tobbe from Tyresö www.roadkillracing.se |

Beginning of october

|

The front is molded in carbon fiber by Kenneth and Tomas. I’m looking, learning and in their way. Very cool to see how they work with carbon fiber! |

2008-09-21

|

There we go! It took about 30 minutes to destroy about 6 months of work. With other words, the metal body is cut off the chassie and sent to the city dump. I cant believe there was so much putty on the body! I know we spent about 40-50 kilos but when you see how thick it is it looks like a lot more! The new rear axle is in place with new 4-lnks. Now for the fun stuff, to assemble the car! |

Middle of september

|

I test-mounted a strut and a front wheel and it looks sweet! I also mounted the rear axle and it looked good! It’s about time to cut away the metal body and finish the build! |

Beginning of september

|

“The black gold” Wow. Kenneth and Tomas at Swecomposite is doing a really good job! It looks GREAT! More pictures from the carbon fiber process will come! |

End of august

|

Jonnie from Lindberg Bros came by with their jig so I can rebuild by rear end. I decided to make the wheel base longer and so the rear axle didn’t fit any more. |

19 juni

|

The Chevelle is back from Swecomposite. The molds turned out really good. Now it’s carbon fiber time in the body shop and cleaning time in my garage. Unfortunately I decided that there will be no racing this year. The engine wasn’t what the seller promised and the body took to much time. At some point you have to realize that you cant work 24 hours a day. Buy there will be a next summer and then I’ll get my C1 license and test the Chevelle! |

May

|

We waxed, waxed, waxed. We put a sort of cardboard on the windows to get them the right height from the body. Soon the molds will be done and we can get the car back home and continue the chassie work. |

Middle of april

|

17 april, The Chevelle arrives at Swecomposite. A couple of months to late…. It’s a shame it took so long. Swecomposite are super busy with work but I’m hoping for the best. Thanks to Alexander from Preem in Gribbylund for letting me use his trailer |

Beginning of april

|

Johan is busy with the body at LSF Custom Paint. He’s a great guy who took time to help me even though he didn’t have the time. And if anyone is wondering, YES a lot of putty used here… |

End of March

|

New engine is a 540 cui! The engine from the states was taken apart for inspection as of corse things wasnt what the seller said. The crank hub was a bit loose so it had damaged the crank snout. And there was a spun bearing on the 2nd and 3rd main cap. So now the engine will be rebuild and made Pro Mod legal. Right now It’s GREAT to work in a engine machine shop (Birka). Big thanks to Anders “Charley” Karling who helped me make custom main caps. |

March 25

|

Big step for ABM Racing. Out of the garage for the first time in 15 months. On the way to LSF Custom paint. Thanks to Tobbe for the help and big thanks to Alexander from Preem Gribbylund for letting me use his trailer! |

Middle March + easter

|

We masked the car and put on some paint, more putty and more paint. It got a good look after all! We put it on the floor in race height and it’s really low. 123cm on the highest point. Johan from LSF Custom Paint will help out with the final touches before it’s taken to Swecomposite. Johan will also help us to paint some details (chrome details, emblems etc) on the finished carbon fiber body when it’s done. |

Beginning of March

|

As always there was a change of plans. We redesigned the front wheel fenders to direct the air away from the wheels. John “The Snake” was here and worked like crazy for 10 hours. Snail-man, Tobbe and Dennis also did a great deal of work. |

End of February

|

Time to get the lines of the body straight! Putty, putty, putty… It’s starting to look OK, but we already spent more than 20-25 kilos! But hey, what old American car in totally straight in the body? |

Middle of February

|

I was down in Norrköping and purchased a scoop. The idea is to mold it to the hood if half the engine will stick out of the hood. I also ordered an engine from the states. It’s a blown 540 cui with a 14/71 blower so hopefully we can test drive the car at the end of 2008. We put some sheet metal on the body to make the molding easier for Swecomposite. Thanks for the help John! Skoot was also here and helped out. |

Beginning of February

|

Metal work around the rear window is complete, the lower side panels are basically done and the Snail-man fooled around as usual. Not a bad week! |

End of January

|

Did some work on the side of the body. The snail-man calls this “styling”, and he worked a lot with this. I also redid the area around the rear wheels and did some work to make the rear window a bit smaller. |

Build pics from 2007

Click on the pictures to get to the photo galleries

End of December

|

The trunk lid has been finished. A little warped and crooked, but it’s nothing a little putty cant fix! |

Middle of December

|

Trunk lid is in place, roof has been welded and the holes for the rear lights has been welded shut. We have to seal the holes prior to the molding. The rear lights will of corse be re-mounted once the carbon fibre body is done! |

Beginning of December

|

Back to work after a trip to the US! Perhaps not the funniest job, but it’s time to do the same thing on the left side as we did on the right side. Good thing the Snail-man is here to bring some joy. I also did some sheet metal work on the trunk lid. |

Beginning of November

|

The roof is adjusted the way we want it. This turned out to be quite a challenge since it got warped when we cut it. We put metal strips to extend the C-pillars and raise the trunk lid. Finally we have room for the wheel tubs! I also want to apologize for the fastback-look. After all, fastbacks are associated with the F-word. You know, the forbidden F-word you never use in a Chevy-garage. (Hint: F*RD) |

End of October

|

The front is done! All thats left is some grinding of the weldings and of corse loads of putty work before we can mold it. When we decided to make the body in carbon fiber we also decided to lengthen the wheel base from 106 inch to 113 inch. Unfortunatley this also means that we have to rebuild and reshape the C-pillars to make room for the wheel tubs. Me and Dennis spent many hours on planning how to do this, and finally we started to cut! This would of corse take a lot of extra time but hey… All we have is time and money! 🙂 |

Middle of October

|

There we go! The front end is starting to get sorted out and after some considerations and measuring we are happy with the result. It looks really SWEET! It has most of the the original looks except for the spoiler. The bumper is actually from a Chevelle ’65. |

Beginning of October

|

The front bumper is in place. Rear bumper and back rear of the body is finished, and it looks really good! Snail-man brings the kind of joy that only the Snail-man can! |

End of September

|

We decided it would be best and easiest if we first built the body of the car from metal. This way we would be able to shape it as we wanted it to get the right look. All the plastic parts were sold and we bought original metal parts instead. Thanks to Snail-man for bringing so much fun and laughter to the garage! |

Beginning of September

|

We make a fresh start from the summers pause when Andreas helped Max Hamrin with his Morris Minor in Pro Street. The body is mounted to see what it would actually look like. Turns out its low. Really low. Just the way we like it We also talked to Swecomposite who will be helping us to make the body 100% carbon fiber! Cool! |

From Sept 2006 to May 2007. Later it was sold to Tobbe from www.Roadkillracing.se

Build pics from 2005

Click on the pictures to get to the photo galleries

Autumn 2005

|

I just picked up the car from Bjurås. The car was purchased from the guy who drove the Bjurås-Camaro back in the 90s. He was also over in the United States and competed in the World Street Finals in Orlando. Now the idea of a 7.50 chassis in a ragger-car is forming. Little did I know at the time how much this project was going to get out of control 🙂 |